When you think of workplace safety, what comes to mind is often personal protective equipment, ergonomically designed workstations, and yellow striped lines on the floor marking machinery and walkways. Safety warehouse guardrail systems are rarely factored in before an accident occurs, even though steel guard rail is a more effective solution for workplace safety, especially in an industrial setting.

1. Why do you need a guardrail

Guard rail systems in warehouse and manufacturing operations protect machinery and provide a safe and efficient work environment while protecting the people working at the facility. Forklifts and other material-handling vehicles are common in manufacturing or warehousing facilities and often move throughout the facility near employees. According to the survey, there are about 85 fatal forklift accidents per year in the United States and accidents that end in serious injury number in the thousands.

While it’s true that operator training can help reduce forklift accidents, creating a safety system in your facility is ideal. Many facilities simply mark the floor with yellow tape for areas that are off limits as well as travel paths for forklifts, but those measures don’t offer real protection for people who are working or passing through the facility. Because of loose government guidelines, each facility needs to take it upon themselves to create a safer environment, and yellow tape certainly won’t stop an out-of-control forklift.

Of course, not all safety barriers are created equal. Most manufacturers build their protective guard rail to have an impact rating of 10,000 pounds traveling at four miles per hour, to account for a forklift and a typical load. This means that if a forklift traveling at four miles per hour hits the guard rail, the guard rail deflects the impact from 12 to 15 inches.

If that same forklift struck a guard rail with a higher impact rating, which is rated at 13,000 pounds traveling four miles per hour, the guard rail would deflect 10 inches or less. A couple of inches might not seem like a big deal, but when your warehouse space is limited, every inch that can be gained for material storage or manufacturing counts.

2. Design what’s right for your facility

Keep these considerations in mind when selecting the right system for your facility.

1) Level of Protection

The key to safety is knowing where you need it and what level of protection you need. What type of traffic does the facility have? Is it mostly people? Pallet jacks? Forklifts? Knowing the traffic type can help determine the level of protection needed.

If the facility has mostly pedestrian traffic, maybe a light-duty guard rail around heavy machinery is all that is needed. If the facility has forklifts zipping around, a heavier-duty guard rail is necessary to protect against accidental collisions.

For example, I have a friend who is a climatic chamber manufacturer. Once he invited me to visit his factory. His factory has many climatic chambers and forklifts running in them. But I didn’t feel in danger because he had installed warehouse guardrails on either side of the sidewalk. This not only ensures the safety of the employees but also the safety of the products.

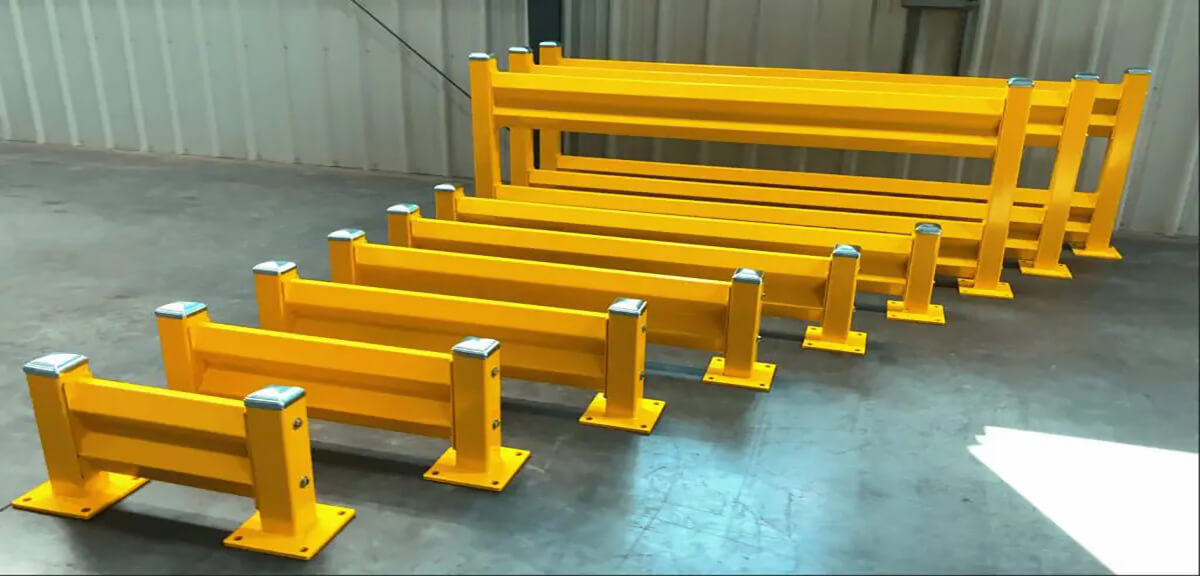

2) Guard Rail Height and Length

After you’ve settled on the level of protection, the next thing to consider is guard rail height and length. This will depend on where in the facility you’re putting the guard rail. A single high guard rail might be all that is necessary around a conveyor, but a double high guard rail better defines a forklift lane around machinery or through a warehouse.

Know how the manufacturer measures their guard rail, too. Many vendors measure from the center of the column to the center of the column, and that will affect how long of a barrier you’ll need to order.

3) Pedestrian Traffic

Then there is pedestrian traffic to consider. Do you need lift-out rails to allow employees to reach guarded machinery for maintenance? Do you need gates to allow personnel through runs of the guardrail?

Knowing how the facility operates and how materials and people flow through it is crucial to creating a safety solution that works for everybody. Take a walk around the facility and do a safety survey to determine the places you need to put guarding and any potential gates.

4) Selecting a Vendor

Selecting a vendor may seem as simple as a Google search, but there can be a little more to it depending on the needs of the facility. Conducting only a brief search and a quick request for a quote may lead to purchasing sub-standard guard rails. A little bit of research will enable you and your customer to select exactly the right kind and combination of safety guarding products that are needed to create an effectively safe environment in the facility. Here are two considerations:

5) Manufacturing Location

The first thing to know is where the guard rail is manufactured. Guard rail systems that are manufactured in the United States have the benefit of being more customizable and are often held to stricter manufacturing process standards than their foreign counterparts. There is also the benefit of being “locally” made, so if you need a replacement part or add-on, you can get that much quicker in the U.S. than from an overseas supplier.

6) Impact Rating

The guard rail should also have an impact rating from the manufacturer based on certified testing of the product. The purpose of certified testing is to demonstrate and prove that it’s able to handle and deflect the specified amount of weight that it was designed to withstand.

Without certified testing, you can’t be sure that the guard rail that you’re purchasing for a facility will withstand the force of a forklift running into it. Ideally, the testing should be done by a registered professional engineer not affiliated with the company to preserve the integrity of the testing process.

3. Conclusion

A manufacturer could make the best guardrail on the market, but it doesn’t help anyone if it’s not being used. Unless you have firsthand experience with a workplace accident or injury due to a forklift, safety guarding isn’t at the top of your facility’s “must-haves.” Of course, once an accident occurs, the value is quickly seen.

That said, customers are becoming more aware of the value of installing a safety guard rail prior to an accident. Designing the right safety barrier system for your facility is crucial to keeping everything and everyone properly protected. Select a vendor that is able to partner with you in designing a safety system that meets your needs.

Think of guard rail as insurance for a facility, equipment, and the products it manufactures. How much will it cost to have production stopped because of damage from a forklift accident? Or to cover a workman’s compensation claim or lawsuit in the event of an injury or worse? Being proactive and installing relatively inexpensive guard rail systems can prevent these types of accidents and provide peace of mind knowing that a facility is safe and equipment and personnel are protected every day.

Leave A Comment